Yes, my oil usage, my carbon footprint, and ways to evade the financial meltdown. All these have taken me away from ham radio for the moment.

All these, plus one other. I won a little applications contest being held by a company called

Plat'Home. They have a line of tiny Linux servers called the OpenMicroServer (OMS 400). These are headless, diskless Linux platforms, based on the

RMI Alchemy au1550 chip -- a MIPS architecture device that runs at 400 MHz. A Compact Flash chip can be installed to serve as a hard drive. I use a 2 GB device. Plat'Home supplies a minimal Linux distribution called SSD/Linux, but you can also install

Debian. (I haven't gone to Debian yet, but may do so.)

My application was a "Home Utility Support System" - a combination of hardware and software that would monitor operation of the home heating and hot water systems with an eye toward analyzing operations and reducing heating costs.

A prelimary report is available

here as a PDF. The installation is shown in the photo at left. (Click on photos for high res.) Physical I/O is through Ethernet connected to a WiFi bridge that hooks into the household LAN, and through the USB to an inexpensive DLP-IO8-G 8-channel data acquisition and control module from

DLP Design.

I built a number of interface devices that monitor the state (on/off) of the oil burner, the hot water circulator, and our three heating zone circulators. (Our hot water is supplied indirectly through a heat exchanger that receives hot water from the furnace "boiler".) The DLP interface also supports

DS18B20 digital temperature sensors. I use two of these to monitor outside ambient temperature and hot water outlet (pipe) temperature.

The software is all developed in

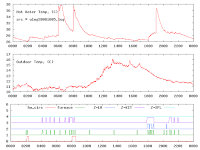

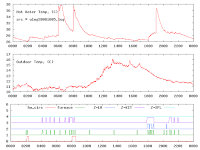

Python to log data every 30 seconds and to do analysis and data plots once a day. A sample run is shown here, as produced by

gnuplot software running on the OMS400. The computer also runs the standard

Apache web server to make data available to any authorized user anywhere on the Internet.

The work is still in progress, but I have a preliminary interesting, if depressing, result. The idle cycle of boiler (when no heat or hot water is demanded) is about one burst of several minutes every 3 hours. This just maintains the boiler's water temperature in its operating range. At a nominal 1.65 gallons per minute burn rate and with the current price of heating oil, that amounts to some $3.00 a day every day of the year!

Furnace people tell us never to let the system cool down, because of the thermal/mechanical cycling and because of possible corrosion problems, but paying ~$1,000 per year to idle is excessive. (I do dial down the operating temperature in the summer months, but we can't go too far or the domestic hot water will not come to full temperature.)

So there is some incentive to continue this project, potentially saving money (for ham work, of course), saving the environment, and having a little fun by the way.

Many thanks to Plat'Home for their support.

Yes, my oil usage, my carbon footprint, and ways to evade the financial meltdown. All these have taken me away from ham radio for the moment.

Yes, my oil usage, my carbon footprint, and ways to evade the financial meltdown. All these have taken me away from ham radio for the moment. A prelimary report is available here as a PDF. The installation is shown in the photo at left. (Click on photos for high res.) Physical I/O is through Ethernet connected to a WiFi bridge that hooks into the household LAN, and through the USB to an inexpensive DLP-IO8-G 8-channel data acquisition and control module from DLP Design.

A prelimary report is available here as a PDF. The installation is shown in the photo at left. (Click on photos for high res.) Physical I/O is through Ethernet connected to a WiFi bridge that hooks into the household LAN, and through the USB to an inexpensive DLP-IO8-G 8-channel data acquisition and control module from DLP Design.

This is an Encore ENRXWI-G "Wireless LAN Extender". I needed to extend my home Ethernet into the basement, for a project I'll describe later. For about $30 (newegg.com), this box saves me an hour or two struggling in my crawlspace for CAT 5 installation. That's a fair trade, I'd say! I bought two of them, with one as a spare.

This is an Encore ENRXWI-G "Wireless LAN Extender". I needed to extend my home Ethernet into the basement, for a project I'll describe later. For about $30 (newegg.com), this box saves me an hour or two struggling in my crawlspace for CAT 5 installation. That's a fair trade, I'd say! I bought two of them, with one as a spare.